Large-format cutting CNC plotter

A CNC cutting plotter is a device that makes it possible to create precise and repeated cuts in various materials such as foils, textiles, rubber, seals and many others. Plate cutting plotters are often used in industrial applications such as furniture manufacturing, advertising and exhibition materials, modelling, construction, sealing technology and more. At the same time, our CNC plotter also appears often in creative industries such as art, fashion and design.

Ask about the GWEIKE CNC cutting plotter

The GWEIKE large-format cutting plotter works on the basis of digital designs that are created using a CAD program. The design is then converted to machine G code that controls the movement of the plotter and sets the cutting parameters. These parameters include cutting speed, material pressure and depth of cut. CNC cutting plotters are characterized by high precision and repeatability of cuts. This makes them ideal for producing large volumes of parts or repetitive cuts that require high quality and precision. These CNC plate machines also enable a reduction in production time and labor costs.

CNC cutting plotters are equipped with various knives, such as oscillating, rotary, V-Cut or trailing knives. Each tool has its own specific properties and applications, which vary depending on the material and the purpose of cutting. The plate plotter can be supplemented with, for example, a marking pencil or an unwinding device for material in rolls.

The advantage of a CNC plotter is its wide use and easy control using a computer. As it is fully automated, large quantities of parts can be easily produced without the need for manual cutting. These machines are therefore ideal for large-scale production. However, CNC cutting plotters also have some limitations. They are not suitable for very thick material.

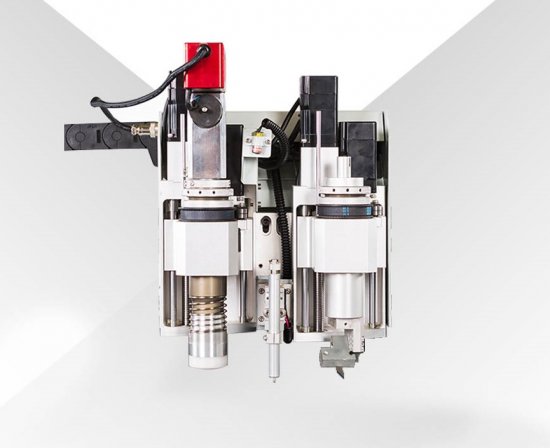

Key components

Large-format plotters consist of three main parts: control unit, movement mechanisms (motors) and tools. The control unit contains software that allows you to program and control the plotter, including setting the speed and depth of cut. Movement mechanisms are responsible for moving the plotter in different directions. The tools are then used to cut the material and can be replaced as needed.

Tool options

- Oscillating cutting knife

- Rotary powered knife

- A dull knife

- Marking pencil

- V-Cut knife

- Spindle with cutter

- Camera for clipping marks

CNC stands for Computer Numerical Control, which means that the control of the plotter is fully automated using computer software that allows precise and repeatable operations. When choosing a cutting plotter, it is important to consider several factors, such as the size of the work area or capacity of the CNC plotter, the type of tool used, the accuracy and speed of the cut, as well as the availability of technical support and service.

Plotter plotters are very useful and versatile machines that enable fast and accurate production of various parts and products. As technology advances, they are becoming increasingly available and used in many industries around the world. Ask us for a new CNC plotter and we will arrange cutting tests of your material and provide you with proper service. All this for the affordable price of a cutting plotter.