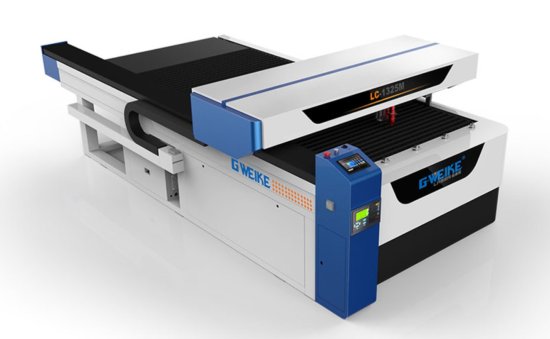

Portal milling machine GWEIKE

The portal milling machine GWEIKE is intended for processing plastic, aluminum or wooden plates. It can also be equipped with a laser cutting head or an oscillating knife. The CNC Router brings easy machining of large-format materials and the range of uses is huge. Do not hesitate to examine the gantry milling machine in high standard equipment for yourself.

Ask for a CNC gantry milling machine

A gantry milling machine is a machine that is used to machine large and heavy workpieces. This type of milling machine is characterized by its robust construction and the ability to machine workpieces from several sides at the same time, which increases the efficiency and accuracy of work. The main part of the gantry milling machine is the gantry, which is a massive frame that surrounds the work area and on which the moving parts of the machine are fixed. This gantry moves horizontally along guides located on the milling machine table, allowing for precise positioning of the tool.

A spindle with milling tools is fixed on the gantry, which can move in three axes – horizontally, vertically and longitudinally. This movement is ensured by precise linear guides and ball screws, which enable high machining precision to be achieved. The gantry milling machine is equipped with numerical control (CNC), which means that all movements of the tool and the workpiece are controlled by a computer based on a pre-prepared program.

CNC router equipment options

- Automatic tool change

- Laser cutting head

- Oscillating cutting knife

- Tool and workpiece probe

- Vacuum clamping of plates

Advantages of gantry milling machines

One of the main advantages of a gantry milling machine is its ability to machine very large and heavy workpieces that could not be machined on conventional milling machines. This is important, for example, in the production of parts for the ship or aircraft industry, where workpieces of several meters in size and weighing several tons are often worked with. Due to its design, the gantry milling machine can perform complex machining operations such as milling, drilling, reaming, tapping and more.

Another advantage is the high rigidity and stability of the machine, which ensures high machining accuracy even when machining hard materials. This is made possible not only by the robust construction of the portal and table, but also by the use of advanced materials and technologies in the production of the machine itself. In modern gantry milling machines, for example, ceramic bearings are often used, which have lower friction and a longer service life than traditional metal bearings.

The gantry milling machine also offers high flexibility in machining different shapes and sizes of workpieces. With the ability to quickly change tools and program different machining cycles, a wide variety of parts with different precision and surface finish requirements can be machined on one machine. This increases productivity and lowers production costs.

Portal milling machines are therefore an essential tool in modern production, where the emphasis is on high precision, flexibility and efficiency. Their robust construction and advanced technologies enable large and complex parts to be machined with high precision, which is key for many industries.