Laser cutting technology

Laser cutting technology is absolutely essential for the industry. These are modern burning machines that are equipped with CO2 or fiber technology. It is the newer fiber lasers that are used in industry to cut metal materials in the form of sheets, profiles and pipes. Laser cutting is very precise and quite efficient. Modern CNC machines have high performances that cover all demand.

I am interested in cutting laser

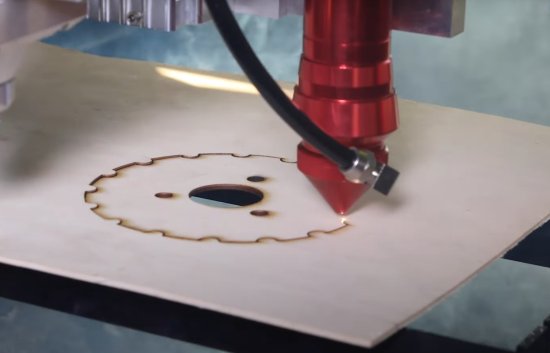

Laser cutting provides a non-contact possibility of dividing or punching, for example, metal sheets. There are also CNC lasers that can machine plastic or wood. At the same time, it is possible to use this technology in a marking laser. There are many applications, and we must not forget to mention laser cleaning or, for example, welding.

Principle of operation

For laser cutting technology, the key element is the source. It is a laser beam generator or radiation created by diodes. The beam is subsequently amplified and, in the case of a fiber laser, is guided into a fiber. At the end of the filament is a laser processing head. The task is to "tame" this technology according to the application. CNC machines for metal have been using this technology since the middle of the 20th century. The efficiency of the solid-state laser is now greater than 30%.

The principle for the operation of this technology is the conversion of electrical energy into light. It is concentrated in one small point. The cut material does not need to be clamped (profiles or pipes do). Sheet metal forming machines equipped with a laser are controlled by a computer and are therefore very precise and fast.

3 laser cutting options

- Sublimation - the material is vaporized by a high intensity of heat and radiation

- Melting - here the metal material is melted at the cut point and auxiliary gases are used to blow the melt away

- Burning - this technology burns the material in an exothermic reaction during laser burning

Advantages of laser cutting technology

- Very thin and perpendicular cut

- A minimum of marbling on the underside of the firing

- Shape diversity and precision

- High efficiency of fiber lasers

- Great variability of laser technology

Application of use

As already mentioned, metals can be effectively split with laser cutting technology. Among the most common are, of course, ordinary structural steel and stainless steel. Metals such as aluminum, copper or brass are no exception. In the case of CNC design, it can be used for plate cutting applications, tube 3D lasers or combined CNC laser cutting machines.

It is possible to cut with a laser, dividing the strength of the material from approx. 0.1 mm to 60 mm, sometimes even more. The performance of the laser source in this technology depends on the application of use and affects both the maximum possible force of the material and also the speed at which this material can be cut. More power means more options and more productivity. It is also important to mention the necessity of using technical assistance gases. The most common cutting gas is oxygen, nitrogen or even compressed air.

Summary

Laser cutting is a key element in modern industry and materials processing. Its ability to cut accurately and quickly brings efficiency and innovation to many industries. With the continuous development of laser technology, this method can be expected to play an even more significant role in the future of industrial production.