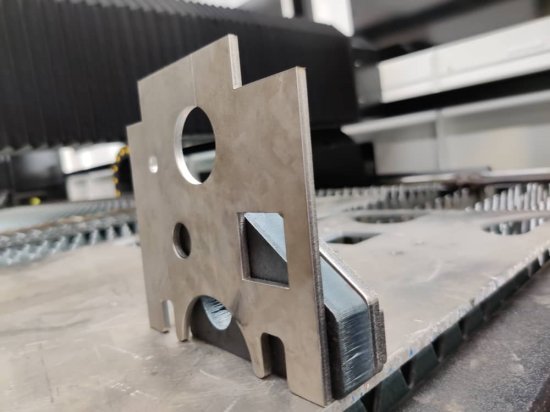

Various metals from fiber laser

Fiber lasers have the ability to burn various metallic materials such as carbon steel, stainless steel, aluminum or copper. The most common application of CNC lasers is for classic or stainless steel. Working with aluminum is not as frequent as in the case of steels, but even so, this production is not completely negligible. Aluminum has the property of fast heat dissipation and its cutting requires higher power of the CNC laser cutting machine at the same thickness as, for example, conventional steel. Copper separation is also not a problem on a fiber laser. Each material requires a different setting of the CNC laser and the same applies to its strength. Based on the required maximum thickness and types of material, we will first recommend the appropriate power of the laser source and the type of process head, and then we will set the parameters in the laser machine system for the required divided material. Below you will find photos of samples of various metals.